The terms CPL and HPL are in widespread use, and the products have been around for many years now, yet people continue to ask questions about the differences in quality and what possibilities the two alternatives offer in terms of products. In the context of laminates however, there are also a number of terms and materials that crop up repeatedly. These are listed below.

The terms CPL and HPL CPL stands for Continuous Pressed Laminates HPL stands for High Pressure Laminates (HPL with a thickness of ≥ 2 mm are, according to the EN 438 standard, compact laminates)

Laminate Description

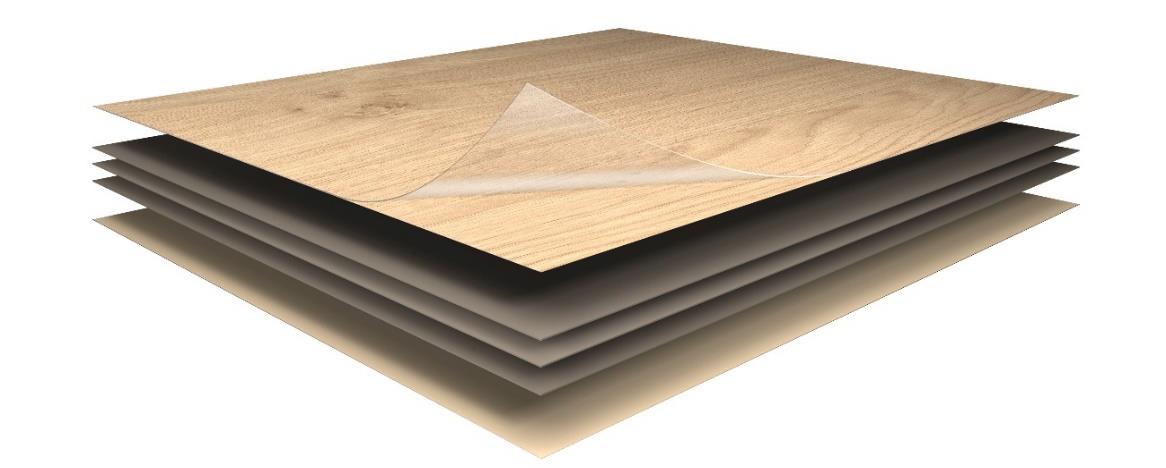

Decorative laminate boards consist of strips of cellulose fibre (paper) impregnated with heat-hardening resins. These are joined using the manufacturing methods described below. The coating layer generally consists of an overlay impregnated with resin, decor paper and sometimes a barrier. The core of a laminate consists of kraft papers that are also impregnated. Applying heat and pressure causes the resins to flow and subsequently cure. Cross-linking of the resins, reinforced by the cellulose fibres of the papers, results in a very dense material with a sealed surface.

Laminate Structure

The laminate structure provides information on the number of layers of paper and their composition, in other words the laminate thickness and the quality requirements are defined. In addition to the decor paper, the number and weights of the core papers and the use of overlay and underlay are also determined.

Manufacturing process

CPL process

The term CPL provides a clue to the manufacturing process; CPL is produced in continuously-operating double-belt presses with a compression force of between 30 and 70 bar and temperatures between 150°C and 170°C. Depending on the thickness of laminate and the length of the pressing zone, the feed speed may vary from 8 to 15 m/min.

HPL process

HPL is produced in discontinuously operating multi-layer daylight presses with compression pressures of between 50 and 90 bar and temperatures > 120°C. In the context of the laminate production process, pressure is very often also quoted in megapascal [MPa]. Daylight presses can have between 10 to 20 layers and each layer can accommodate approx. 8 laminate boards with a nominal thickness from 0.50 to 0.80 mm. Depending on the loading of the press and its maximum temperature, the entire pressing cycle including recooling takes between 20 and 60 minutes.

Advantages and disadvantages

CPL process

The continuous production process of CPL dispenses with waste being incurred on length cuts and facilitates online finishing. This means that job-related lengths are flexible and can be produced economically. It is also possible to produce thin laminates, < 0.5 mm thickness, and to supply a specific range of thicknesses as rolled goods.

HPL process

This manufacturing process enables compact laminates (laminates ≥ 2 mm thick) and surfaces with deep textures to be produced. In combination with multi-layer daylight presses it is also, in theory, possible to produce one single board, although this would never be advisable from an economic point of view.